Biotech solutions - fine tuned to your requirements

Pharmaceutical substances manufacturing

Enzymatic processing of raw materials

Glycosaminoglycans and mucopolysaccharides

Glycosaminoglycans and mucopolysaccharides are widely available in animal tissue. Most often those are extracted from raw materials such as lungs, intestinal mucosa, trachea, cock’s combs, skins, etc.

Most often those are extracted from raw materials such as lungs, intestinal mucosa, trachea, cock’s combs, skins, etc.

Glycosaminoglycans and mucopolysaccharides are widely used in medicine, veterinary medicine, pharmaceutical and cosmetic industries.

The most important and commercially successful product line is focused on pharmaceutical substances, such as heparin and hyaluronic acid ( which is also actively used in cosmetics).

Advantages of enzymatic processing

General principle of extraction:

The extraction process destroys the surrounding tissues and nucleoid proteins, which are covalently linked to the Glycosaminoglycans and Mucopolysaccharides. Those can be released by either alkaline or enzymatic hydrolysis. When using proteolytic enzymes, there is no need for traditional alkaline hydrolysis!

ADVANTAGES OF USING ENZYMATIC METHOD IN COMPARISON WITH ALKALINE:

- Increased yield and quality of products

- Reduced production costs, effluent volumes and solid waste

- Stable & flexible extraction process

General scheme for heparin extraction

Raw materials:

- Intestinal mucosa

- Lungs

- Trachea

- other

Pre-processing:

- Flushing with pre-press fluid

- pH regulation

Enzyme dosing and hydrolysis:

- Heating and holding at optimum temperature

- Monitoring of pH, Brix and degree of hydrolysis to the desired end point

- Heat inactivation of enzymes

Subsequent processes:

- Processing of the extract

into crude heparin

- Filtration

- Absorption by resin

- Sodium chloride rinsing

- Alcohol deposition

- Drying

General scheme for chondroitin sulphate extraction

Raw materials:

Cows cartilage, pigs, chickens or marine species.

Pre-processing:

- Flushing and removal of connective tissue.

- Adding water

- PH regulation

- Heating

Enzyme dosing and hydrolysis:

- Heating and holding at optimum temperature.

- Monitor pH, Brix and degree of hydrolysis to the desired end point.

- Heat inactivation of enzymes.

Subsequent processes:

- Further processing of

- chondroitin sulfate.

- Filtration.

- Cleaning.

- Drying.

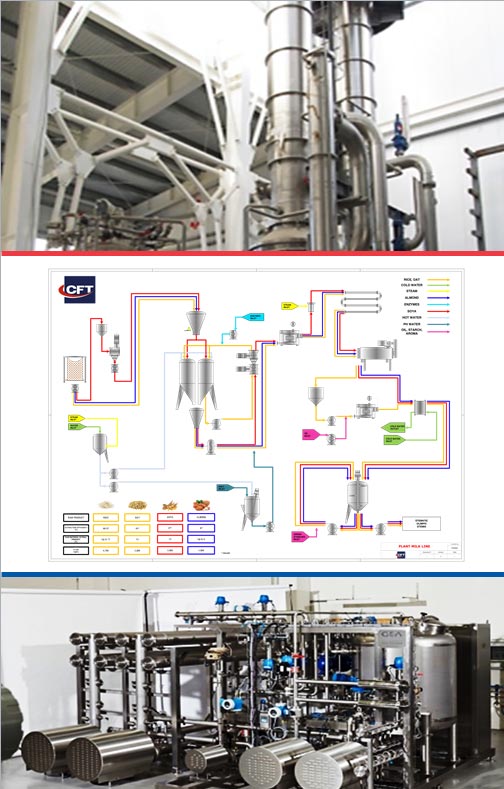

Engineering and equipment

Our experts, in collaboration with leading Russian and European engineering and technology companies, design biotechnological productions, in particular for all projects described in this presentation, and equip them with machinery from leading European manufacturers: CFT Group, ICF & Welko (Italy), GEA Group, Flottweg (Germany), Bertsch-Laska (Austria) and others

Our successes so far

Alcohol

Deep grain processing

Microbiology & Biotechnology

Pet food & treats

Fruits, berries & veggies processing

Grain beverages / plant milk

GET BIOTECHNOLOGICAL SOLUTIONS TO MEET YOUR TARGETS!

- Technological audit

- Transfer of out-of-the-box biotechnological solutions

- Supply of enzymes and biotechnological tools

- Engineering and special conditions of technological equipment delivery

- Technological service