Biotech solutions - fine tuned to your requirements

Benefits of Enzymatic Hydrolysis deep corn processing

(in comparison to acidic hydrolysis)

Enzymatic hydrolysis. An absolute priority in the industry

Currently, 90% of enterprises in the industry use enzymatic hydrolysis for deep processing of corn

Market leaders – Amilko, Aston-ADM, Gulkevichsky KZ, NewBio and others are using enzymatic technologies. All of them work with us as partners and are growing rapidly.

Enzymatic hydrolysis allows you to

- Significantly improve economic indicators

- Diversify production

- Reduce the hazard class with tightening environmental legislation;

- Produce in-demand products (maltodextrin, liquid malt, etc.)

- Improve quality

What can be achieved using enzyme technologies

- Increase in starch yield due to enzymatic release of up to 70% of bound starch and improved leaching

- Reduce lock-up time to 8-10 hours

- The ability to produce various types of syrups

- Elimination of the use of aggressive chemicals (reduction of facility hazard class);

- Reduce cost of additional chemicals;

- Reduce filtration costs and wastewater treatment plant loads;

- Reduce and stabilize the volume of free starch in the pulp fed to the dryer.

- Solve the issue with carbon deposits and sticking of the product in the dryer and transporters;

- Reduce moisture content of the pulp by 6-10%. Thus, at the current load, the energy load on the press and dryer is reduced, and at full load, their productivity increases.

- Possible reduction in gluten loss

Trends

- Large consumers of syrups buy products manufactured according to their specifications with a certain spectrum of sugars;

- The most manufacturers can rebuild their technology in agile manner and increase the range of products;

- Tightening of environmental regulations;

- Drive to reduce manufacturing hazard class;

- Increase in demand and cost of syrups with improved quality characteristics (color, ash content).

Issues with Acidic Hydrolysis

- Limited consumer properties and range of manufactured products and, as a result, limited customer base

- High class of industrial hazard and risks associated with tightening environmental legislation

- Cost of acid and its further neutralization;

- Formation of salts in the process of acid neutralization and additional costs for cleaning the syrup from them.

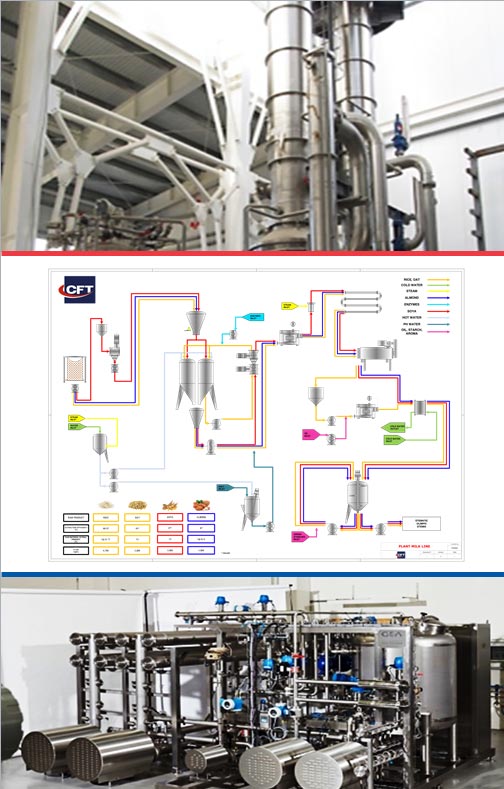

Engineering and equipment

Our experts, in collaboration with leading Russian and European engineering and technology companies, design biotechnological productions, in particular for all projects described in this presentation, and equip them with machinery from leading European manufacturers: CFT Group, ICF & Welko (Italy), GEA Group, Flottweg (Germany), Bertsch-Laska (Austria) and others

Our successes so far

Alcohol

Deep grain processing

Microbiology & Biotechnology

Pet food & treats

Fruits, berries & veggies processing

Grain beverages / plant milk

GET BIOTECHNOLOGICAL SOLUTIONS TO MEET YOUR TARGETS!

- Technological audit

- Transfer of out-of-the-box biotechnological solutions

- Supply of enzymes and biotechnological tools

- Engineering and special conditions of technological equipment delivery

- Technological service