Efficiency of this technology has been proven at 150 farms in Russia

Production of hydrolyzed,bioavailable and hypoallergenic grain components for forages Technology and Equipment

hydrolyzed grain bases for feeds

High digestibilty - Hypoallergenic - Better feed and biological value

Efficient technology for enzymatic grain processing:

- Provides an optimal carbohydrate-protein balance of feed

- Increases feed intake

- Accelerates the weight gain of young stock and fattening animals

- Increases daily milk yield

- Solves the problem of sugar and protein deficiency in the industry

- Significantly reduces premixes consumption

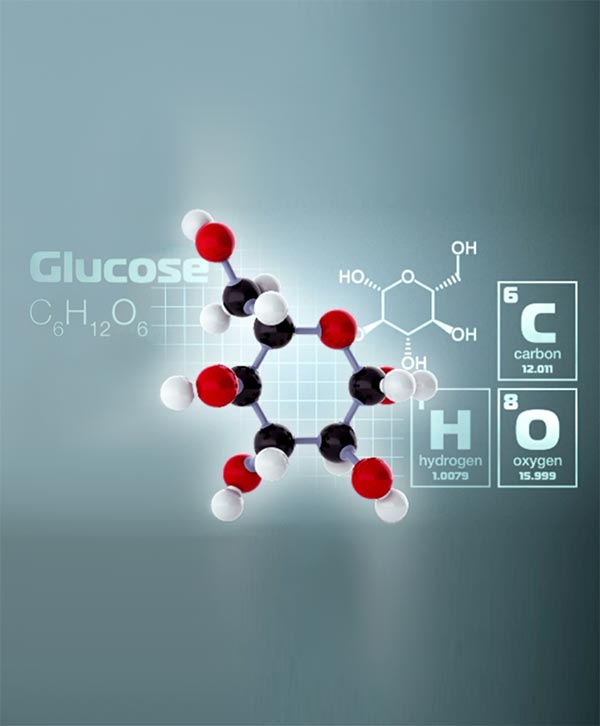

Output delivers easily digestible low molecular weight sugars, up to 77% consisting of GLUCOSE, which is 10 times cheaper than the current market offerings

Other components (proteins, fats, etc.) remain in the same quantities, but in a more digestible form

Economics

Glucose is ideal for balancing sugars in animal diets

The total contents of easily digestible monosaccharides is 17.7%, including:

- maltose 3.8%

- glucose 13.0%

- sucrose 0.9%

- It also introduces sugar into the diet, up to 77%, consisting of glucose

- Without the use of technology, the content of simple sugars does not exceed 1.5%

- High-quality glucose costs 80-100 rubles / kg in Russia

- Balancing sugars in diets based on beet molasses costs 25-28 rubles / kg of molasses

- With this technology, the cost of glucose production is up to 9 rubles / kg

Savings from the use of our technology in comparison with other methods of balancing the diet of animals with respect to sugars, on average, is up to 25 rubles / day for 1 head

Payback period = 6-9 months

content. rationing

During the milking period, the mammary gland uses up to 85% of the glucose available in the body for the synthesis of lactose. Based on 1 kg of milk, the mammary gland needs about 70 g of glucose. The more glucose is available, the better the milk production potential is. Glucose is also needed for the development of viable eggs.

Contents:

- Dry matter - 30-35%

- Carbohydrates - 15-17%

- incl. glucose from the total sugar content - 60 - 75%

- Share of crude protein - 13-14%

- Nutritional value of 1 kg of dry matter of hydrolyzed grain components is 1.5-1.7 feed units. (excluding high feed digestibility)

Rationing

- lactating cows - 2-3 liters per day per head;

-

calves aged:

- from 2 to 6 months 0.5 liters per head per day;

- from 6 to 12 months 1.0 l per head per day;

- over 12 months 2 liters per head per day; - weaning piglets (1-2 months) - 0.1-0.2 liters per head per day;

- fattening pigs - the entire daily ration of concentrated

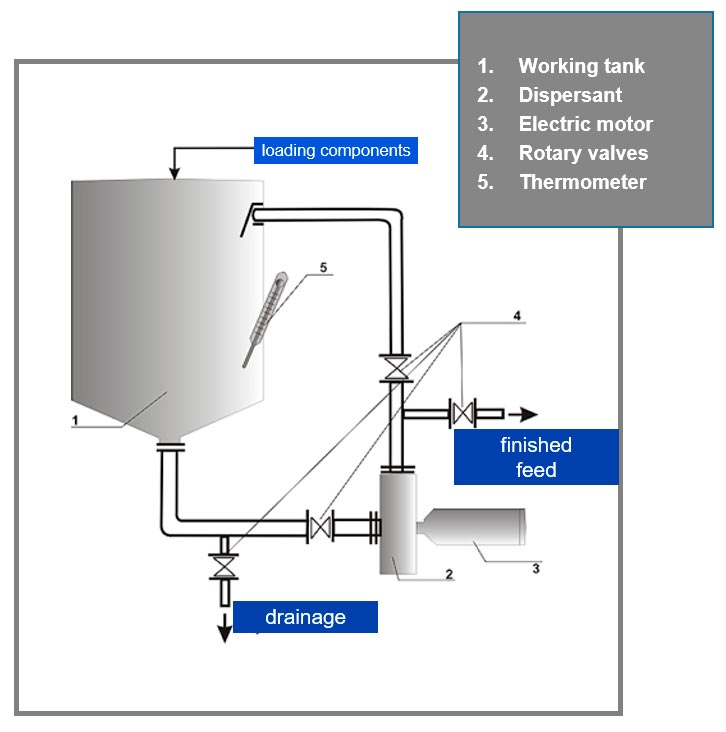

Engineering and equipment

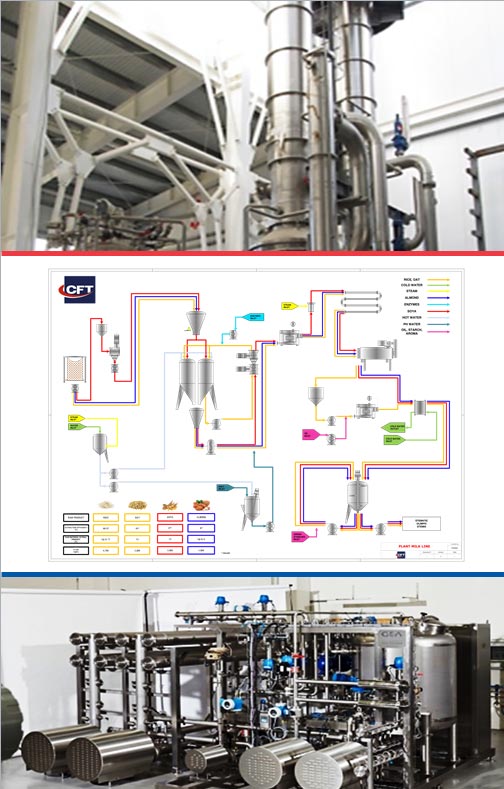

Our experts, in collaboration with leading Russian and European engineering and technology companies, design biotechnological productions, in particular for all projects described in this presentation, and equip them with machinery from leading European manufacturers: CFT Group, ICF & Welko (Italy), GEA Group, Flottweg (Germany), Bertsch-Laska (Austria) and others

our successes so far

Alcohol

Deep grain processing

Microbiology & Biotechnology

Pet food & treats

Fruits, berries & veggies processing

Grain beverages / plant milk

GET BIOTECHNOLOGICAL SOLUTIONS TO MEET YOUR TARGETS!

- Technological audit

- Transfer of out-of-the-box biotechnological solutions

- Supply of enzymes and biotechnological tools

- Engineering and special conditions of technological equipment delivery

- Technological service