Biotech solutions - fine tuned to your requirements

Frontia Fiberwash – improving the efficiency of wet corn processing

Frontia® – improving the efficiency of wet corn processing

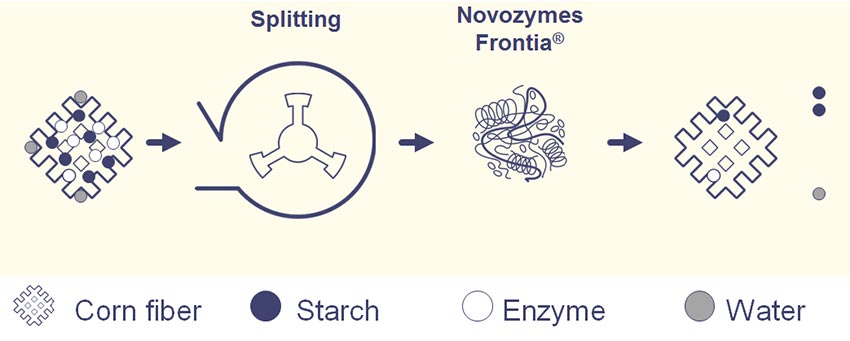

In 2021, Novozymes, in collaboration with SYMBIO, industrialized new, efficient and transformative starch processing technology called Frontia® at the largest enterprises in the industry

This technology makes it possible to conduct a wet process with an additional increase in the output of starch whilst decreasing the volume of steeping water required and lowering the load on treatment facilities. It also helps decrease energy consumption for evaporation and provides other economic and technological benefits

** An Internal audit is required to understand the economic effects of the deployment of Frontia technology for your specific business

Frontia Fiberwash – improving the efficiency of wet corn processing

- Increase in starch yield (enzymatic release of up to 70% of bound starch and improved leaching of free starch)

- Reduced and stabilized amount of free starch in the pulp fed to the dryer. Solving the problem with carbon deposits and sticking of the product in the dryer and transporters

- Reduced moisture content of the pulp (6-10% lower). At the nominal capacity, the energy consumption of presses and dryers is reduced, which allows to increase the productivity of the enterprise during the period of peak loads

- Reduced grain steeping time (8-10 hours less)

- 100% utilization of all steeping water and reduction of the load on wastewater treatment plants

- Reduced gluten loss

- Fewer dryer stops - increased uptime

- Stabilization of feed quality

Technology launch stages Frontia® Fiberwash

On average, the project will pay-off within 6 to 9 months

- Technical audit

- Potential assessment. Pulp research. Laboratory tests

- Preparation of a feasibility study

- Sample tests for setting up equipment

- Industrial start-up technology

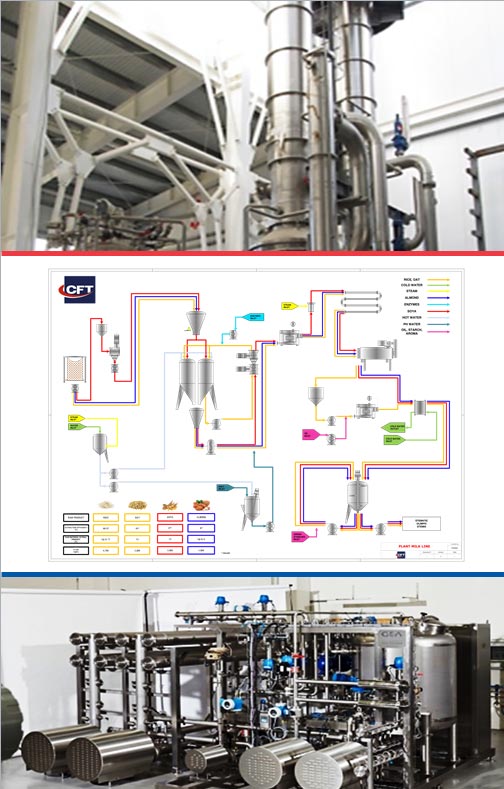

Engineering and equipment

Our experts, in collaboration with leading Russian and European engineering and technology companies, design biotechnological productions, in particular for all projects described in this presentation, and equip them with machinery from leading European manufacturers: CFT Group, ICF & Welko (Italy), GEA Group, Flottweg (Germany), Bertsch-Laska (Austria) and others

Our successes so far

Alcohol

Deep grain processing

Microbiology & Biotechnology

Pet food & treats

Fruits, berries & veggies processing

Grain beverages / plant milk

GET BIOTECHNOLOGICAL SOLUTIONS TO MEET YOUR TARGETS!

- Technological audit

- Transfer of out-of-the-box biotechnological solutions

- Supply of enzymes and biotechnological tools

- Engineering and special conditions of technological equipment delivery

- Technological service